The automation revolution in manufacturing is a transformative shift driven by technologies like AI, robotics, and the Industrial Internet of Things (IIoT). This revolution enhances efficiency, precision, and quality by automating repetitive or dangerous tasks, freeing up human workers for more skilled roles. Key benefits include increased productivity, reduced costs, improved quality control, and greater flexibility, though challenges like initial investment and potential impacts on employment need to be addressed.

Key technologies and drivers

- Artificial Intelligence (AI): AI algorithms power industrial robots for precision and speed, and help in analyzing data for better quality control and predictive maintenance.

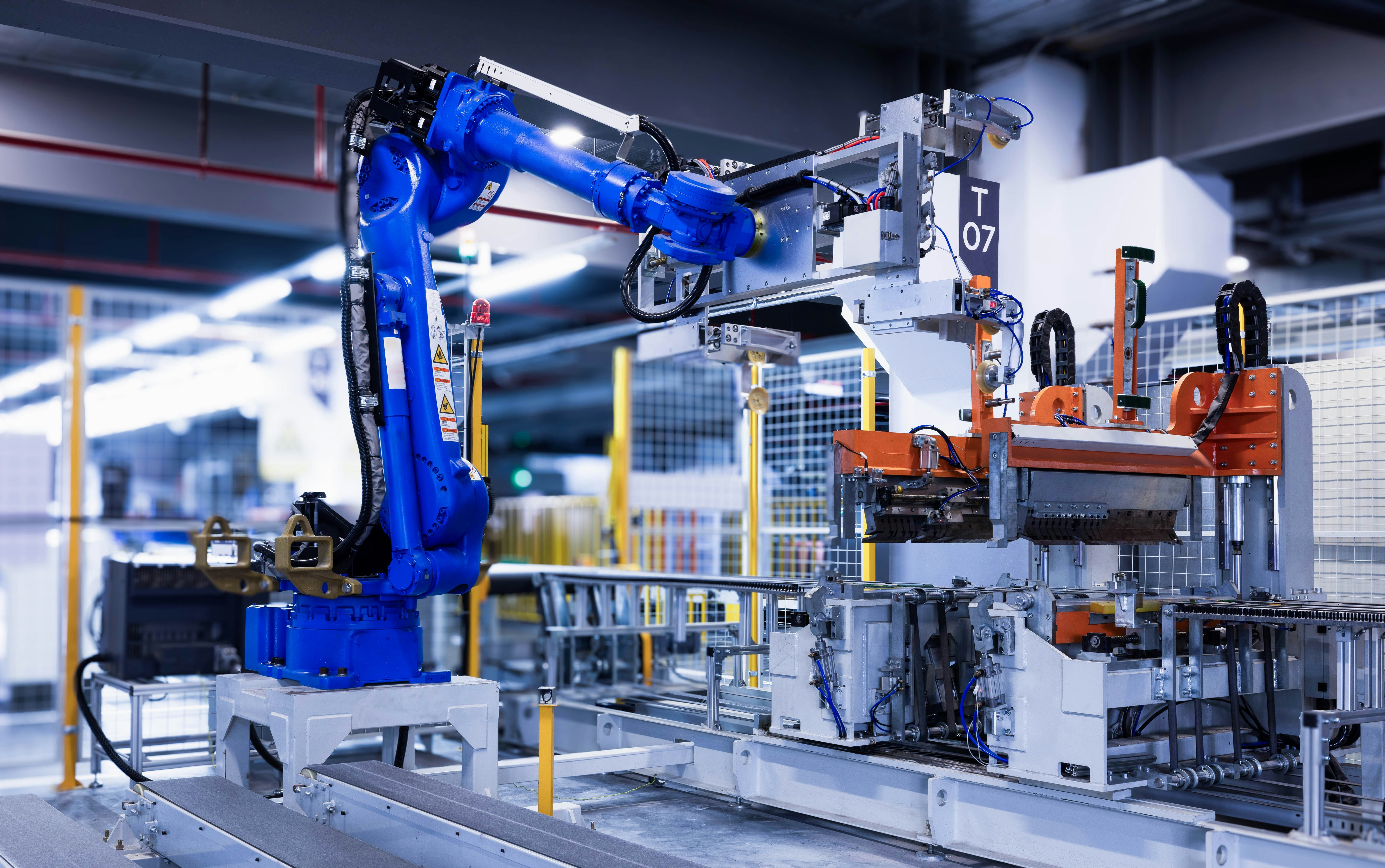

- Robotics: From large industrial robots to collaborative robots (cobots), these machines perform tasks with high accuracy and can work continuously, boosting production and taking over dangerous jobs.

- Industrial Internet of Things (IIoT): This connects devices and systems across the production line, enabling real-time data collection, better inventory management, and increased agility.

- Computer-controlled systems: These include Programmable Logic Controllers (PLCs), which can be virtualized on systems-on-a-chip for greater flexibility and performance.

Benefits of the revolution

- Increased efficiency and productivity: Automated systems can run 24/7 with high precision, minimizing errors and maximizing output.

- Improved quality and consistency: Automation reduces defects and allows for better quality control through consistent execution of tasks and real-time data monitoring.

- Reduced costs: By increasing output and reducing labor costs, automation can lead to a significant return on investment despite the initial cost.

- Greater flexibility and responsiveness: Manufacturers can adapt more quickly to market changes by using automated systems that can be reprogrammed or scaled as needed.

- Enhanced safety: Automating dangerous or repetitive tasks reduces workplace injuries and frees up human employees to focus on more skilled and safer activities.

Challenges and considerations

- Initial investment: Implementing automation requires a significant upfront cost for technology and integration.

- Impact on employment: The transition raises concerns about job displacement, although it also creates demand for new roles in managing and maintaining these new systems.

- Skills gap: A need exists for a workforce with new skills in areas like data analysis, robotics, and AI.

- Implementation hurdles: Companies must navigate the complexities of integration and ensure systems can effectively interact with each other and with human workers.